I thought I would share the voyage of discovery which is more like a roller-coaster of ups and downs:

Today, I expected to spend half an hour mounting the air compressor under the bonnet. Like three hours later, it's finally done. Here is the time line:

11:00 - 11:05: Drive car into driveway, choosing a position to minimise inconvenience to other dwellers in our complex. Already depressed at the forgone conclusion that I'm going to be in someone's way... it's just a matter of time and chance.

11:05 - 11:20: Spent 15 minutes finding ideal locating position - not a flat spot anywhere. I ended up settling on the only free space left, with a 5-10 degree slope. Doesn't present a problem, it's just not how I had in mind.

11:20 - 11:30: Mounted, cables routed, earth point chosen. The captive nut's in the body took M5 bolts I had - sweet. Didn't have to go to hardware store AGAIN and didn't have to drill any holes or use tek screws. Done in half an hour! Internal celebratory dance.

11:35 - 11:45: Tested, big spark, some kind of thud and left licking my wounds after conclusion that I have probably blown something up. Oddly the negative terminal on the batter sparked in addition to the positive wire I had in my hand. Licking wounds at the prospect that I could have just blown my face off with sparks and gas from battery.

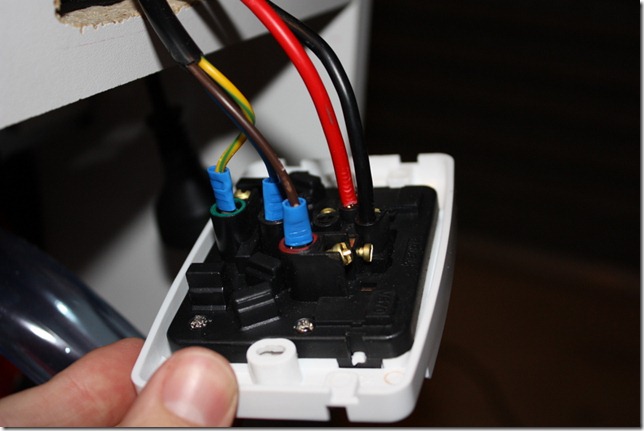

11:45 - 12:00: Un-bolted air compressor, taken apart for diagnosis. Made leads for my stupid cheap multimeter that the leads broke on. Tested resistance in circuit as I assumed there must be a short somewhere. Unable to find short.

12:00 - 12:15: Wired in large fuse to confirm fault existance... fuse wouldn't blow, but neither would anything work. Sick of idiots driving past leaving me one foot of room, and 6 feet of room on the other side. Resigned to fact that I'm going to smash the next person that drives so close to me with the nearest metallic object.

12:15 - 12:30: Look like an idiot with home-made 14gauge wire multimeter test probes testing for voltage... I have voltage all the way to the relay for the compressor... Hmm, maybe the compressor relay is dirty.

12:30 - 12:45: Compressor relay seems fine, but contacts appear dark, scrub with sandpaper anyway. Made no difference, found another relay, still doesn't work. No lights on indicator switch. Relay won't tick.

12:45- 13:00: Convinced my earth must be bad, relocate from body bolt to negative pole of starter batter - success, as the indicator light illuminates, but odd clicking sound from relay, and no compressor action. Convinced relay still could be failed, swapped over, no difference.

13:00 - 13:15: Removed wires from inside guard and tested on starter batter, success, lights and compressor... but oh damn, that means my auxiliary battery is stuffed. The thud I heard could have been some internal failure. Tested and still had voltage but assume still it's stuffed. Resign to fact that this is an opportunity to replace with deep cycle battery.

13:15 - 13:30: Unbolted auxiliary battery bracket, removed connectors and taped up positive connector so it doesn't earth out.

13:30 - 13:45: Retested with compressor on just poles of auxiliary batter - success! what... how?! Inspected inside of earth connector of auxiliary batter, dirty and cruddy. 10 minutes spent cleaning connector. All fixed!

13:45 - 14:15: Re-installed battery, re-assembled and re-installed air compressor. Routed wires, crimped connector. Still sore over fault discovery process.

14:15 - 14:30: Clean up, numerous tools everywhere, oh how I hate this bit.

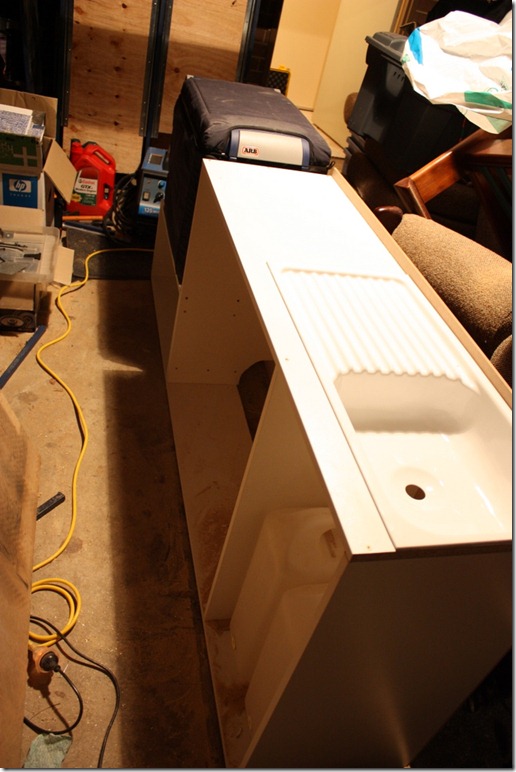

I am continually amazed at how long things take! Cassie has done the first coat of paint on the kitchen unit - looking good. I would like to start doing the fun stuff, like installing water pump, inverter, fuse panel etc... but I must wait till the painting is all done. No pictures today, but hey, it'll give you all a break.